Reckerth Spindle Repair

Specialist Reckerth Spindle Repair Service

When production stops due to spindle failure, downtime costs can escalate fast. Our specialist Reckerth spindle repair service provides a rapid, precision-engineered solution for all Reckerth spindle models, returning OEM performance and reliability while minimising disruption.

Precision Repair for Bearing & Drawbar Failures

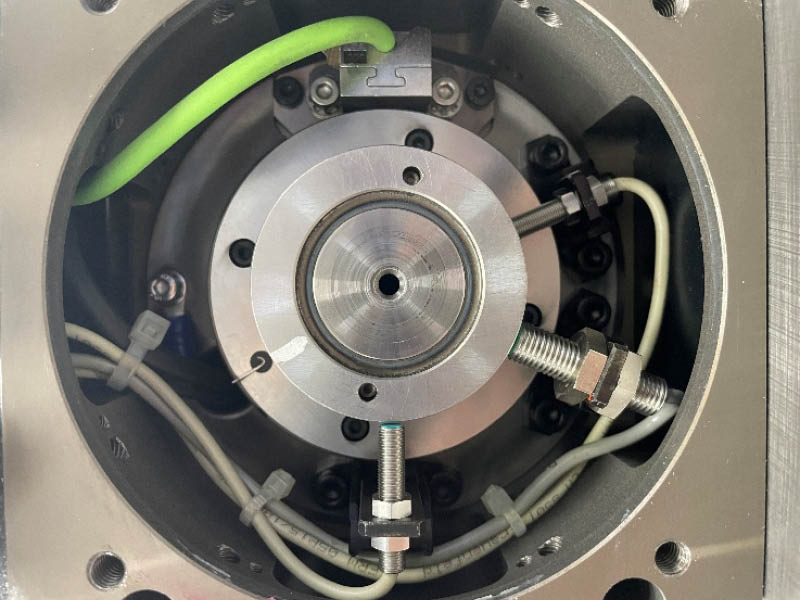

The most common reason for Reckerth spindle failure is bearing degradation, often caused by contamination, lubrication breakdown or excessive load. Our engineers dismantle and inspect every spindle, fitting new high-precision ceramic bearings and ensuring correct preload and balance to OEM specification. Each rebuild undergoes fine measurement verification to guarantee long-term performance.

Drawbar issues are another major cause of lost productivity. Worn drawbar springs, fatigued gripper segments, or malfunctioning actuation systems can lead to poor tool retention and chatter. We fully rebuild drawbars using premium replacement components, then dynamically test clamping force using our OTT pull force equipment to ensure reliable tool holding under load.

Full Function Testing with Encoder Verification

Every Reckerth spindle repair includes a complete run-test and performance verification. Using our custom test rigs, we measure temperature, vibration, noise, balance, and speed consistency under load to confirm the spindle meets operational standards.

A crucial part of this process is encoder testing and calibration. Many Reckerth spindles rely on accurate encoder feedback for CNC positioning and speed control. We test each encoder for signal accuracy, phase alignment, and resolution integrity.

To reduce downtime, our facility holds a full range of encoder replacements in stock, ensuring same-day replacement where required. This capability allows us to complete urgent Reckerth spindle repairs without waiting for manufacturer lead times.

Why Choose Our Reckerth Spindle Repair Service

- Rapid turnaround with full traceability

- In-house dynamic balancing and thermal testing

- Stocked bearings, encoders, and drawbar components

- UK & European collection and delivery

- Warranty-backed repair with performance certification

Our technical team specialises in the diagnosis and repair of Reckerth spindle assemblies across machining centres, grinders, and high-speed applications. If you’re experiencing vibration, tool slip, or encoder errors, contact us today for a professional inspection and quotation.

For expert Reckerth spindle repair or to arrange a visit to our facility, please call us on 01778 421739 for a quote. We are fast, experienced, and our work is guaranteed.