Kessler Spindle Repaired to OEM Standard

96-Hour Turnaround: Kessler Spindle Repaired to OEM Standard After Coolant Jacket Leak Causes Bearing Failure

Our spindle repair team has recently completed a rapid turnaround for an automotive customer on their Kessler machining centre spindle which had suffered premature bearing failure due to a coolant jacket leak. The repair, completed and returned to full service in just 96 hours, highlights our technical expertise and commitment to minimising customer downtime & shortening their supply chains.

Coolant Leak Leads to Bearing Damage

The customer reported rising spindle temperatures and increased vibration during operation. Upon inspection, our engineers identified a coolant leak within the spindle’s internal jacket, allowing fluid ingress into the bearing cavity. This contamination led to lubricant dilution, corrosion, and ultimately catastrophic bearing failure.

Our initial strip-down revealed corrosion marks on the front bearing housing and coolant residue throughout the bearing stack. Using precision inspection tools, we confirmed that both the bearing set and coolant seal assembly required replacement.

Full Rebuild and Precision Testing

Because we carry the necessary Kessler spindle bearings and sealing components in stock, our team was able to start the rebuild immediately. The spindle housing was chemically cleaned and pressure tested to verify the integrity of the coolant circuit before assembly.

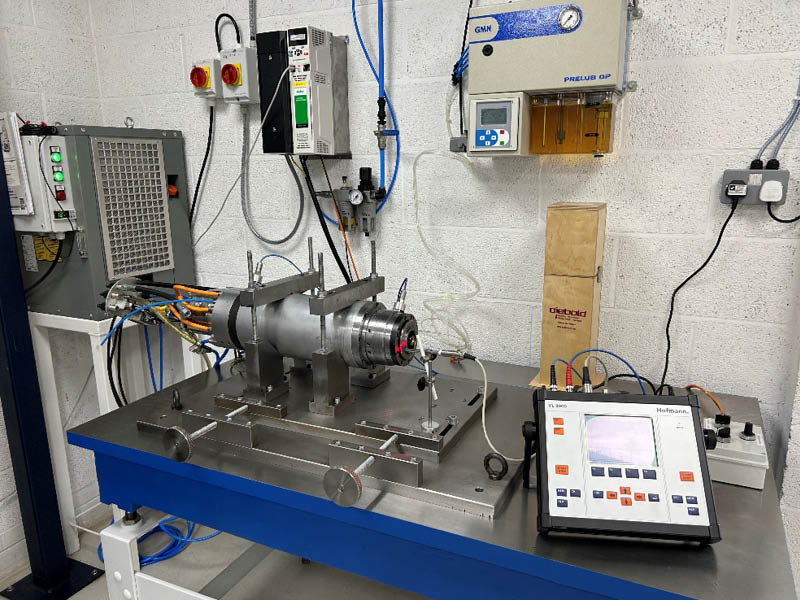

New super-precision angular contact bearings were installed and preloaded to factory specification. The coolant jacket was resealed and tested at operating pressure to confirm zero leakage. The fully rebuilt spindle then underwent dynamic balancing, thermal soak testing, and vibration analysis on our in-house test rig to ensure compliance with OEM performance standards.

Within 96 hours of collection, the repaired Kessler spindle was reinstalled and commissioned back into production with verified results matching original factory performance for temperature, vibration, and runout.

Rapid Response, Proven Results

This case demonstrates our ability to deliver fast, high-precision spindle repairs even when complex mechanical and coolant system failures occur. By maintaining a large inventory of Kessler spindle components including bearings, seals, and coolant hose assemblies we eliminate costly lead times and return spindles to production swiftly.

Our spindle repair service includes:

- In-house diagnostic and pressure testing

- OEM-grade bearing and seal replacement

- Full performance verification and certification

- Expedited turnaround and installation support

If your Kessler spindle shows signs of coolant leakage, bearing noise, or temperature rise, our repair specialists can rebuild it quickly and reliably helping you get back to full production without delay.

For expert Kessler spindle repair or to arrange a visit to our facility, please call us on 01778 421739 for a quote. We are fast, experienced, and our work is guaranteed.