On-Site Spindle Services

On-Site Spindle Removal & Refit

Providing everything needed to get your machine tool back up and running, safely, efficiently, and with full accountability.

A Complete Turnkey Solution – From Breakdown to Rebuild

At Spindle Systems (UK) Ltd, we understand that every hour of machine downtime costs your business money. That’s why we offer a fully managed, on-site spindle removal and refit service—delivering a true turnkey solution from start to finish.

Whether you’re dealing with spindle failure, scheduled maintenance, or performance degradation, we provide everything needed to get your machine tool back up and running—safely, efficiently, and with full accountability.

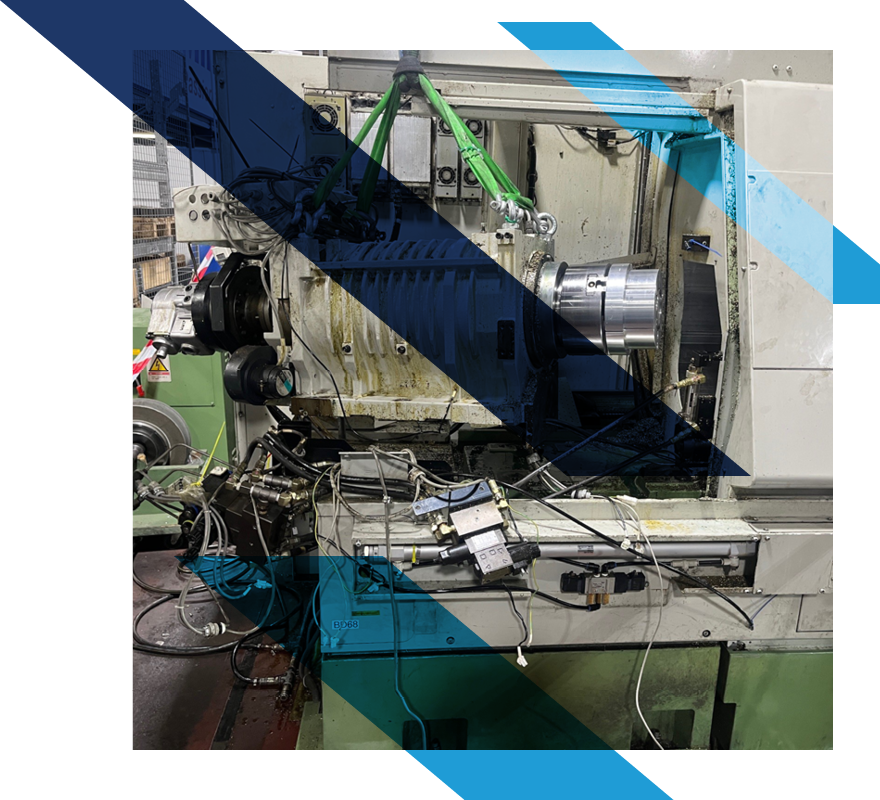

On-Site Spindle Removal

Our skilled directly employed engineers arrive on-site equipped to handle the complete removal process:

Secure disconnection of coolant, air, encoder, and lubrication systems

Safe removal of the spindle from the machine tool

Full documentation of spindle condition and machine interface

Fast, clean, and damage-free extraction

We handle the entire job with no need for third-party contractors, keeping the process streamlined and fully controlled.

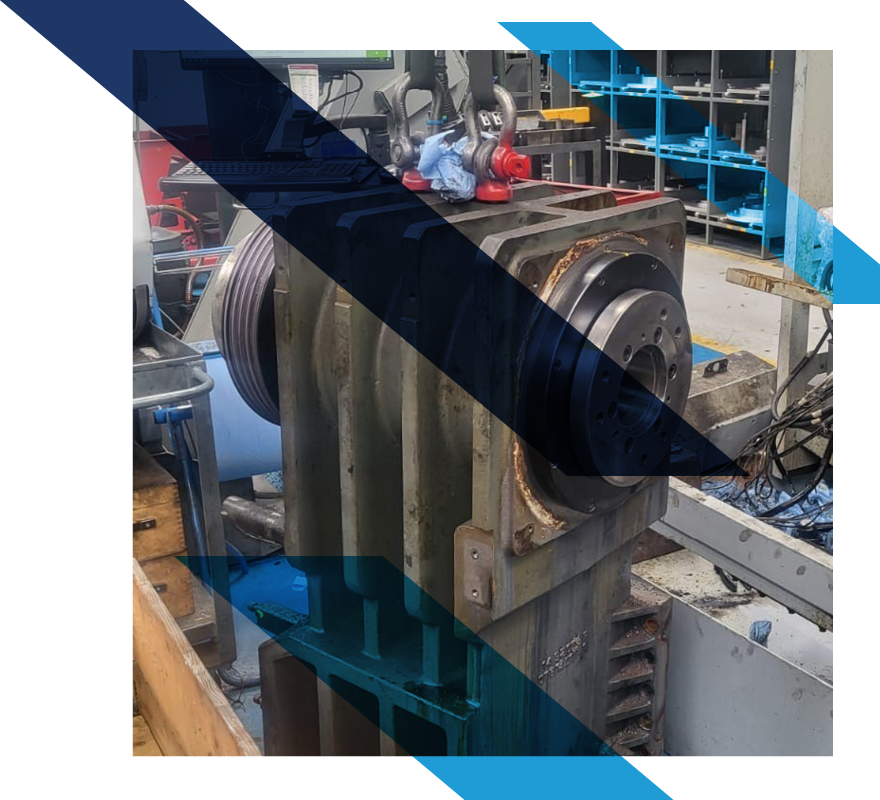

Transport to Our Repair Facility

Once removed, your spindle is carefully packaged and transported to our UK-based facility, where our expert technicians carry out a complete rebuild and testing process.

In-House Spindle Repair

Your spindle undergoes a full diagnostic inspection, followed by precision repair using OEM-spec components and advanced technology:

CMM measurement and geometric inspection

Dynamic balancing to ISO standards

Drawbar force, encoder signal, and runout testing

Full-speed operational testing under load

Every repair comes with a detailed test report, giving you full traceability and confidence in the quality of our work.

On-Site Refit & Commissioning

Once the spindle is fully repaired and tested, our team returns to your site to complete the job:

Reinstallation into the machine tool

Accurate alignment and reconnection of all services

Functional checks including runout verification and tool clamping force

Assistance with commissioning and return to productio

This means you benefit from a fully closed-loop service – from breakdown to rebuild to recommission – handled by one experienced team.

Why Choose Our Turnkey Service?

Minimise downtime with rapid response and full service delivery

Eliminate third-party delays with one trusted provider

Ensure full traceability and performance validation

Reduce risk with expert handling and OEM-quality repair

Nationwide coverage across the UK

Our turnkey spindle service is trusted by leading OEM manufacturers, subcontractors, and CNC operators across a wide range of industries—from aerospace to automotive, general machining to high-precision toolmaking.

Let Us Handle Everything

With Spindle Systems (UK) Ltd, you don’t need to coordinate multiple service providers or worry about transport and reassembly. We take full responsibility for the spindle’s lifecycle—so you can focus on production.

Get in touch today to schedule an on-site removal and refit or to speak with a spindle specialist.