Spindle Testing Specialists

Comprehensive Spindle Testing

Returning your spindles to full operational precision

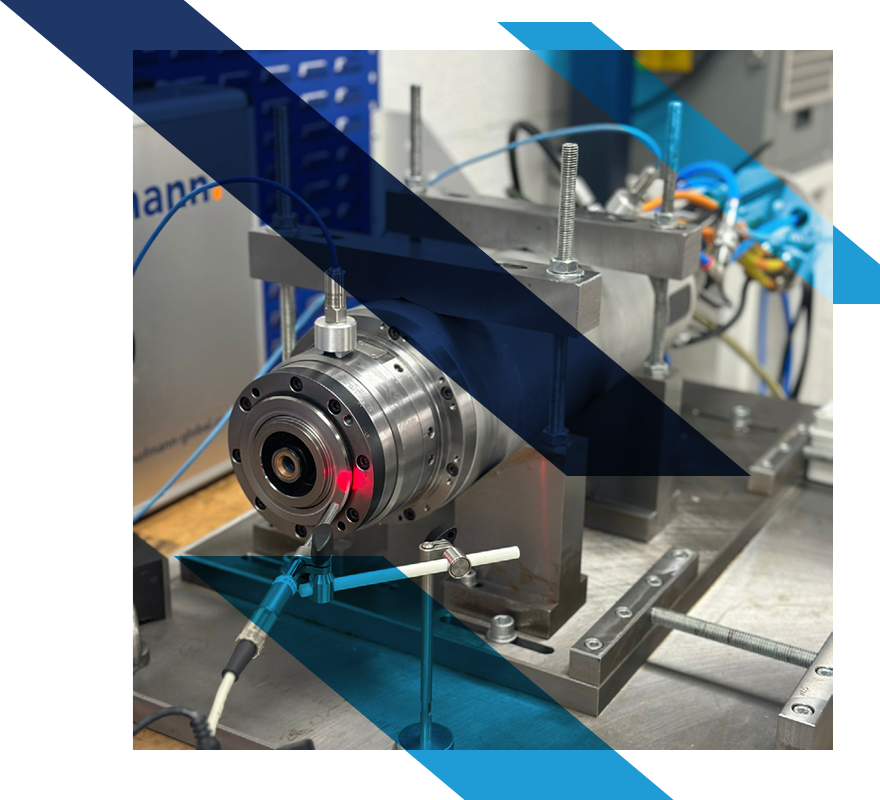

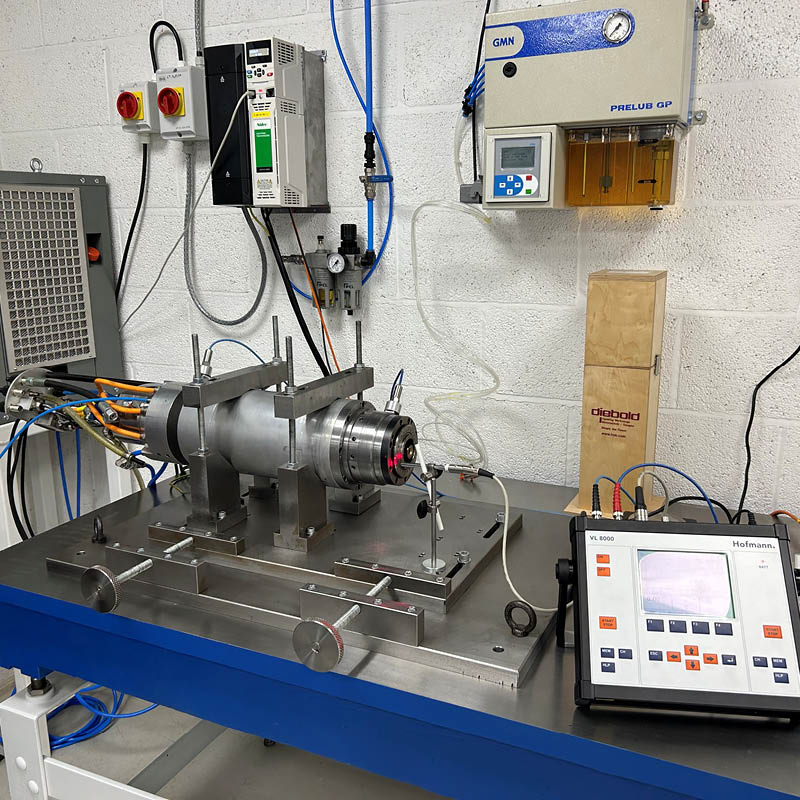

Post-Repair Testing & Quality Assurance

At Spindle Systems (UK) Ltd, we don’t just repair spindles, we return them to full operational precision through a meticulously controlled and fully documented testing process. Every repaired spindle is put through a comprehensive series of performance and quality assurance checks to ensure it operates as intended, or better.

Final Testing: What We Measure

After the mechanical rebuild and dynamic balancing process is complete, each spindle undergoes multi-point testing in our dedicated test bay:

Drawbar Pull Force Testing

Accurate measurement of clamping force for all taper types using calibrated drawbar tester produced by OTT

Ensures proper tool retention and elimination of tool vibration during operation

Compared against OEM specifications and recorded for traceability

Encoder & Sensor Signal Verification

Oscilloscope capture and analysis of encoder waveforms

Verification of pulse integrity and signal timing for speed control and positioning accuracy

We test a range of encoder types including incremental, absolute, TTL, and analogue systems

Vibration & Noise Analysis

Dynamic balancing validation at full speed

Use of vibration sensors and software to monitor bearing behaviour

Checks for early signs of imbalance, resonance, or bearing degradation

Runout Checks (Taper & Shaft)

Precision dial indicator or laser measurement to verify:

- Spindle taper runout

- Front and rear shaft deviation

Tolerances checked to within 2 microns or OEM specification

Thermal Stability & Bearing Preload

Controlled test cycles to monitor:

- Temperature rise over time

- Bearing preload behaviour under speed and load

Ensures thermal expansion and component alignment meet expected norms

Full-Speed Run & Load Simulation

Spindles are run at operating RPM or beyond (if required) under simulated load

Observation of noise, temperature, current draw, and acceleration profiles

Ensures the spindle is ready to go back into production with zero surprises

Test Reports & Certification

Every tested spindle comes with a detailed performance report, including:

Measured drawbar force values

Encoder signal plots (waveform images)

Runout and balance data

Temperature and vibration profiles

Technician inspection sign-off

Optional video footage of the test run

This transparent documentation gives our clients total confidence in the reliability and precision of every spindle we return.

Final Quality Assurance – Built for Reliability

Our testing process mirrors real-world application demands—because we know a spindle’s performance on our test bench must translate directly to real-world cutting conditions.

Whether for high-speed milling, heavy-duty turning, or precision grinding, we validate every aspect of spindle functionality to deliver a worry-free return to service.

Test-Verified. Ready for Production.

All spindles leave our facility fully tested, certified, and production-ready, with full technical documentation included.

Need help reinstalling? Our on-site spindle removal and refit service ensures a seamless handover from testing facility to your machine tool.